By Annina Winkler, Investment Manager

Wanted: packaging innovation to increase paper performance

In my previous blog post, I wrote about the problem of packaging waste and why we need alternatives to plastic. For all the benefits plastic provides, it is fiendishly difficult to get rid of. Recycling infrastructure is missing or deficient in many places, and most plastic ends up in landfill or circulating in sensitive ecosystems like the ocean. This is why many packaging players are taking a second look at paper, which provides more flexible end-of-life options.

Paper breaks down quickly, making it a good candidate for commercial composting facilities. It is also more easily recyclable, with as much as three-fourths of all paper products recycled globally. This is compared to only around 20% for plastic. As Mondi, a major packaging producer, has stated: “Use paper packaging where possible; use plastic packaging where useful.”

Sentiments like these will likely, in the coming years, drive somewhat higher growth for the global paper packaging market compared with plastic. But paper is a complex product and using it in packaging is not always straightforward. For one thing, paper loses out to plastic on a few important metrics: its production costs are higher than plastic, and it is more land- and water-intensive to make.

It also simply doesn’t work quite as well as packaging material—underpinning Mondi’s statement. Emerald has identified several factors where paper lags—especially in food and beverage applications:

- Strength: Paper gets soggy when wet and tears easily, even when dry.

- Barrier properties: Paper provides little protection for perishable food items. It struggles against four main culprits:

- Moisture: This can make fresh foods dry out and frozen products lose their crunch.

- Oxygen: This causes discoloration, loss of nutrients and overall rancidity.

- Grease: This can seep from food items into paper wrapping, degrading it.

- Odor: Paper provides weak defense against unpleasant smells.

- Non-stickiness: It can be a struggle to scrape food away from paper after the two materials have adhered.

- Ethylene inhibition: Ethylene is a naturally occurring biproduct of fruits, vegetables and other fresh produce. It can cause the product to ripen rapidly and spoil if not inhibited by some property of the package.

- Antimicrobial properties: Bacteria, fungi and other microbes will build up on packaging if given a chance, leading to reduced shelf lives for the product and potential for cross-contamination.

- Transparency: Being able to see what is inside a package can be very useful.

Solving these problems is hardly an easy task, but they will need to be addressed if paper is to make greater inroads into the packaging space. Many startups—including our portfolio company Paptic—are inventing new types of coatings that may help, particularly when it comes to boosting paper’s strength and barrier properties.

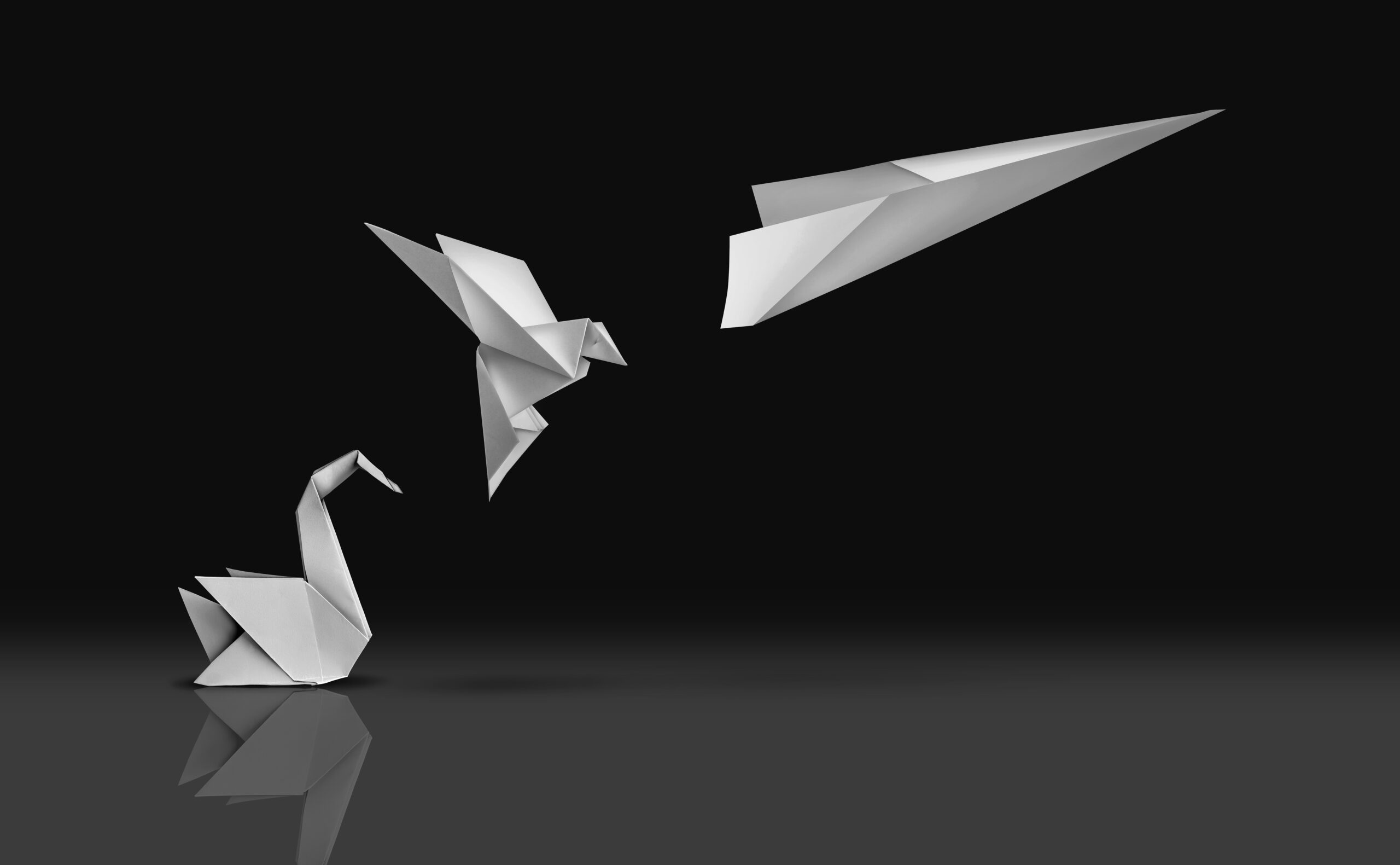

Pushing the paper envelope

Innovation is key to increasing paper’s viability as a packaging material across a range of applications. While paper is not likely to fully replace plastic across every use case, improving its performance can help mitigate some of the tradeoffs packaging players are struggling with as plastic’s end-of-life issues grow. We at Emerald will continue to push the (paper) envelope with bold deal-making that makes the packaging market greener, more circular and more sustainable.