By Aline Rotzetter, Senior Investment Manager – Advanced Materials & Sustainability

The growing urgency to transition towards a circular economy in plastics has led to increased scrutiny of the materials and processes that define the industry. With plastic production projected to  double by 2050, ensuring sustainability is no longer optional; it is a necessity. While the industry is familiar with the “reduce, reuse, and recycle” strategy for plastic, one often overlooked factor is the role of additives.

double by 2050, ensuring sustainability is no longer optional; it is a necessity. While the industry is familiar with the “reduce, reuse, and recycle” strategy for plastic, one often overlooked factor is the role of additives.

Additives are both a blessing and a curse. A blessing, because they enhance the properties of plastics, offering benefits such as flexibility, processability, and resistance to environmental factors. However, they are also a curse, as they pose significant challenges for circularity and health. This article explores how corporations can innovate within this space, addressing the challenges posed by additives while leveraging opportunities to improve plastic circularity.

The Role of Additives in Plastics

Plastics rely on various additives, which fall into four primary categories:

- Functional Additives: These improve processing or application performance, including plasticizers (for flexibility) and flame retardants (for fire resistance).

- Colorants: Dyes and pigments that provide aesthetic and functional coloration.

- Fillers: Substances like calcium carbonate that lower costs and sometimes enhance mechanical properties.

- Reinforcements: Materials such as glass or carbon fibers that improve strength and stiffness.

The global plastic additives market exceeds $100 billion, with functional additives accounting for nearly half of the market. Their extensive use makes it imperative to find ways to mitigate their negative impact on circularity.

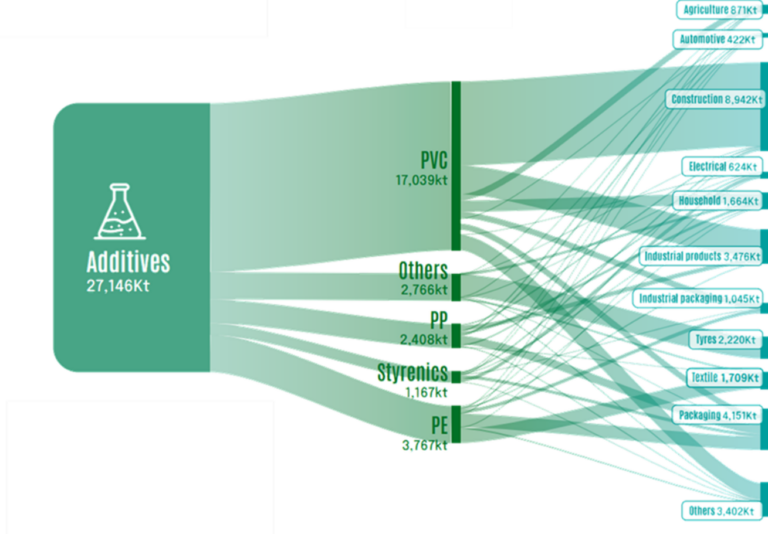

Additive Distribution Across Polymer Types and Application Areas

Source: https://www.e-a.earth/wp-content/uploads/2023/11/2023_Additives-report.pdf

The Environmental and Circularity Challenges of Additives

Despite their benefits, additives create obstacles in achieving a sustainable circular economy. These challenges arise in several key areas:

- Plastic Waste and Environmental Impact

- Only 10% of plastic waste is recycled, with around 25% ending up in the environment.

- Additives, which are not chemically bound to plastics, leach into ecosystems, posing risks to human health and biodiversity.

- Health Concerns and Regulatory Pressures

- Over 13,000 additives and monomers have been identified, of which 7,000 have been tested for hazardous properties and 3,200 have been classified as potentially hazardous, revealing a significant knowledge gap.

- Phasing out restricted additivies, so called legacy additives, is challenging. Studies show that 16% of new PVC floorings still contain restricted substances, primarily originating from recycled content.

- Regulations worldwide, are tightening to restrict and phase out harmful additives. However, the vast variety of additives and the lack of transparency regarding the plastic composition present significant challenges.

- Plastic Waste Sorting and Recycling Barriers

- Carbon black, commonly found in many plastic products, disrupts near-infrared (NIR) sorting, making it difficult to accurately identify and separate these materials for recycling.

- Density-altering fillers complicate sink-float separation processes.

- Abrasive additives such as glass fibers damage recycling equipment.

- Decomposition and Contaminants in Recycling

- The most commonly used mechanical recycling process today cannot remove additives. Additives remain in the mechanically recycled plastic and impair the quality..

- This also applies to odors and colorants, which persist in mechanically recycled materials and limit their applications.

- In additon, decomposition during high-temperature processing can release hazardous byproducts.

Given these significant challenges, businesses must focus on designing solutions that enhance circularity rather than impede it.

Key Innovations and Investment Opportunities

While additives present challenges, they also offer opportunities for innovation. Companies can drive progress by focusing on five key investment areas:

- Non-Hazardous Additives

- Replacing additives of hazardous concern with safer alternatives is a top priority. So-called “regrettable substitutions,” where a harmful additive is replaced with another harmful substance, must be avoided.

- Key criteria for investment include performance, processability, and scalability.

- Traceability and Sorting Technologies

- Transparency in the plastic supply chain is critical for circularity.

- Digital product passports and additive tracers can improve traceability,sorting and recycling.

- While object recognition technologies currently lead in cost-effectiveness, additive tracers may play a complementary role in the future.

- Design for Circularity

- Companies should design plastic products, including fromulation, in such a way that they can be reused and/or recycled.

- Less is often more and a simple formulation with few additives in small quantities can contribute to a better circularity.

- New processing technologies also play a key role by enabling the reduction or complete elimination of additives.

- Initiatives like ReciClass offer guidelines for designing for circularity, specifically in regard to additives.

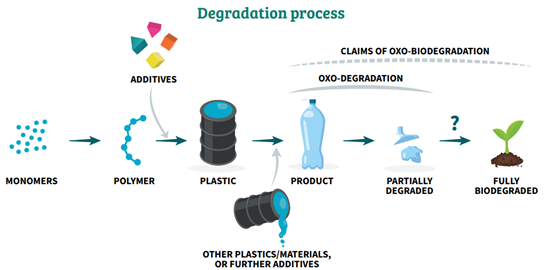

- Additives for Plastic Degradation

-

- Startups are exploring additives that accelerate plastic degradation when exposed to environmental conditions.

- The key challenge is ensuring complete biodegradation rather than generating microplastics.

- Open questions remain about the impact on recyclability and overall value destruction. For instance, does it make sense to degrade durable polymers, or should we use biodegradable alternatives instead?

5. Additives for Recycling Enhancement

-

- These additives improve the quality and usability of recycled plastics.

- Examples include heat stabilizers, chain extenders, and compatibilizers.

- Example: Compatibilizers help blend immiscible polymers, such as PP and PA, enhancing recycled material properties.

Conclusion: Strategic Pathways for Corporations

Corporations must take a proactive approach to integrating circularity into their plastic strategies. The most critical areas of focus for additives include:

- Replacing hazardous additives to comply with evolving regulations and improve consumer safety.

- Investing in advanced sorting and traceability technologies to close information gaps in the value chain.

- Innovating in plastic design to ensure compatibility with existing recycling infrastructure.

- Exploring controlled degradation solutions while considering their long-term implications.

- Enhancing recyclability through targeted additive development.

Short-term opportunities lie in recycling additives that improve material quality, while long-term success will depend on designing plastic products for circularity from the outset. By prioritizing innovation, collaboration, and sustainability, corporations can turn the challenges of plastic additives into a catalyst for a truly circular economy.

Final Thought: The transition to a circular plastics economy is both a necessity and an opportunity. Businesses that invest in smart solutions today will not only comply with regulations but also secure a competitive advantage in the sustainable future of plastics.

References

- United Nations Environment Programme (UNEP). Chemicals & Plastics Technical Report. Available online.

- Market reports from Fortune Business Insights, MarketsandMarkets, Verified Market Research, Grand View Research, etc.

- Environmental Action (E-A). (2023) Additives Report. Available online.

- PlasticsEurope. Plastics: The Facts. Available online.

- Ellen MacArthur Foundation. Introduction to the Circular Economy. Available online.

- Adapted from Ellen MacArthur Foundation and PlasticsEurope.

- Zero Waste Europe. Designing for Real Recycling, Not Plastic Lock-in. Available online.

- RecyClass. Design for Recycling Guidelines. Available online.

- COTREP. Available online.

- Imperial College London, Molecular Science & Engineering. Addressing Plastic Additives. Available online.

- University of Birmingham. The European Regulatory Strategy for Flame Retardants – The Right Direction but Still a Risk of Getting Lost. Available online.

- Wiesinger, H. et al. (2024). Legacy and Emerging Plasticizers and Stabilizers in PVC Floorings and Implications for Recycling. Environmental Science & Technology.

- Rochester, J. R. et al. Bisphenol S in Food Causes Hormonal and Obesogenic Effects Comparable to or Worse than Bisphenol A: A Literature Review. Proceedings of the National Academy of Sciences (PNAS). Available online.

- UNEP. Press Release: Pivotal Fourth Session of Negotiations on Global Plastics Treaty Opens. Available online.

- Royal Society of Chemistry (RSC). Explainer: Additives for Degradable Plastics. Available online.

More from Emerald on plastics and materials:

Tech you should know about: digital reuse systems

Tech you should know about: functional barrier coatings for sustainable packaging and materials